article

Gaining ground on SCM use

Increasing energy efficiency through advanced digital tools is helping cut carbon by reducing power consumption. However, there are some emissions that are much harder to deal with: those which occur with the calcination of limestone and formation of clinker.

Supplementary cementitious materials (SCMs) can be used to bring down the clinker factor

These emissions cannot be eliminated in the same way, and would need to be captured and stored or utilised, using technology that is still in the relatively early stages of development. While the cement industry waits on this – and even once it is widely available – a practical and feasible alternative is the use of supplementary cementitious materials (SCMs), which can be used to bring down the clinker factor.

What are SCMs?

SCMs can be naturally occurring materials or arise as a by-product of other industrial processes. The Global Cement and Concrete Association (GCCA) groups SCMs according to how they harden: hydraulic SCMs harden in the presence of water (like Portland cement) and include granulated blast furnace slag (GBFS) and burnt oil shale. Pozzolanic materials require the additional presence of dissolved calcium hydroxide (Ca(OH)2) – a by-product of the hydration of Portland cement – in order to harden. These include fly ash, silica fume, calcined clays, burnt rice husk and natural pozzolans. Hydraulic cements have a higher early age strength, while pozzolans continue to gain strength for a longer period, giving a higher long-term concrete strength. Both have been proven in construction applications. Limestone is not classified as either hydraulic or pozzolanic but also contributes to the hardening of concrete, putting it in an SCM category all of its own.

The growing acceptance of blended cements in the United States

SCMs have been in use for many decades and are already widely accepted in some markets. For example, in India and Brazil, it is common to use flyash and slag to reduce the clinker factor to as little as 65%. However, the uptake of SCMs is typically dependent on both the availability of SCM sources and regulatory acceptance. In the US, in the last couple of years, we have seen a groundswell of support for Portland Limestone Cement (PLC), a blended cement that uses a higher limestone content to reduce the clinker factor without affecting performance.

What is PLC?

Portland Limestone Cement is almost the same as OPC (Ordinary Portland Cement), except that within the mix, up to 15% of clinker can be replaced with limestone. The Portland Cement Association states: ‘Portland-limestone cement (PLC)…works the same, measures the same, and performs the same, but with a reduction in carbon footprint of 10% on average.’ As of November 2022, all but two US states had accepted PLC, with the remaining two planning to accept. Back in March 2021, the ratio was 34 states accepted, seven planning to accept, and eight considering. It’s evident that there is a real and fast-paced movement in favour of PLC.

Portland Limestone Cement

Of all the blended cements, PLC is an easy ‘yes’ for the US. It doesn’t require any additional technology beyond what a cement plant would already have. It uses a material the plant already has ready access to, so there’s no need to find a stable supply of some other SCM. The increase in limestone – by up to 15% – does not alter cement performance, strength or quality. It can be used as a 1-to-1 replacement for OPC.

Adding limestone to the cement mix is not a new practice. It’s been used in amounts up to 5% since 2004, and in amounts up to 10% since 2007. In 2012, ASTM C595 and AASHTO M 240 defined Portland-Limestone Cement, Type IL, with up to 15% limestone in blended cement specifications. However, the dramatic increase in market share is more recent.

US Geological Survey data shows blended cement shipments totalling 218 707 metric tonnes in January 2021, growing 181% to 615 236 t by December 2021, and by a further 329% up to June 2022, reaching more than 2.6 million t. By October 2022 the figure surpassed 3 million t, an increase of more than 1300% in just 22 months. Of course, PLC doesn’t account for all blended cement shipments, but it is taking the lion’s share. What’s driving this increase?

It helps that organisations like the state Departments of Transportation, the Federal Aviation Administration and others have accepted PLC. And, in a hot market, it also helps that reducing the clinker factor enables cement plants to produce more cement. Their one tonne of clinker can now make 1.10 tonnes of finished product. Of course, the real global benefit is the reduction in CO2 emissions.

What is the process impact of PLC?

Adding up to 15% limestone to the cement mix does come with some challenges in the finish mill stages. Limestone and clinker have different physical properties and so different grinding behaviours. This can lead to challenges in achieving the desired particle size distribution and can increase energy consumption required for grinding. The presence of limestone can also lead to increase moisture absorption during grinding, which can affect the flowability and handling characteristics of the cement. The return – both in financial terms, and environmental – on producing PLC versus OPC will depend in part on your finish mill system. The Portland Cement Association reports that, on average, a Portland Limestone Cement has ‘an 8.3% lower carbon footprint than a Portland cement in the US’. The increased grinding energy required to achieve the requisite fineness is what stands in the way of further reductions.

Grinding PLC in a ball mill vs a VRM

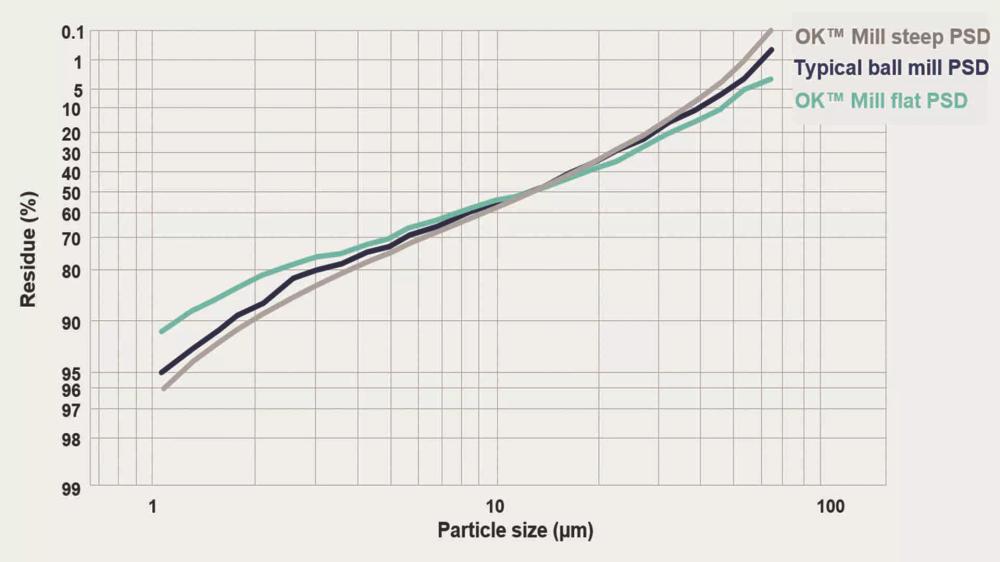

The most common cement grinding systems in the USA are closed circuit ball mills and VRMs. Portland Limestone Cement (PLC) can be ground in either system, although the grinding mechanisms differ, resulting in some key differences between the two. In addition to being more efficient than ball mills, VRMs also allow for more control of the product particle size distribution, and the use of a hydraulic system provides greater control over the grinding process.

In cement products there is a relationship between the Blaine, which is the average surface area for all the particles, and specific sieve residues or individual particle sizes. The most common sieve size used for Portland cements is 45 micron (325 mesh).

Although it varies according to individual clinker reactivity, for OPC this relationship is well established to ensure the needed cement strength is achieved. Typically, for OPC, Blaine is 3800 cm2/kg and the 45 micron residue is 4-5% (depending on the type of grinding system and separator).

When easier to grind materials, such as limestone, are added to the mill feed they change the product particle size distribution to Blaine relationship. The easier to grind material makes a higher quantity of finer particles, which in turn makes it easier to reach the targeted Blaine value. However, the harder clinker particles do not reduce to the fineness needed to achieve the cement strength required. Therefore, the product target Blaine has to be increased until the clinker is ground to the required fineness. This change is easier to make in VRMs, such as FLSmidth’s OK™ Mill than in ball mills.

Ball Mill

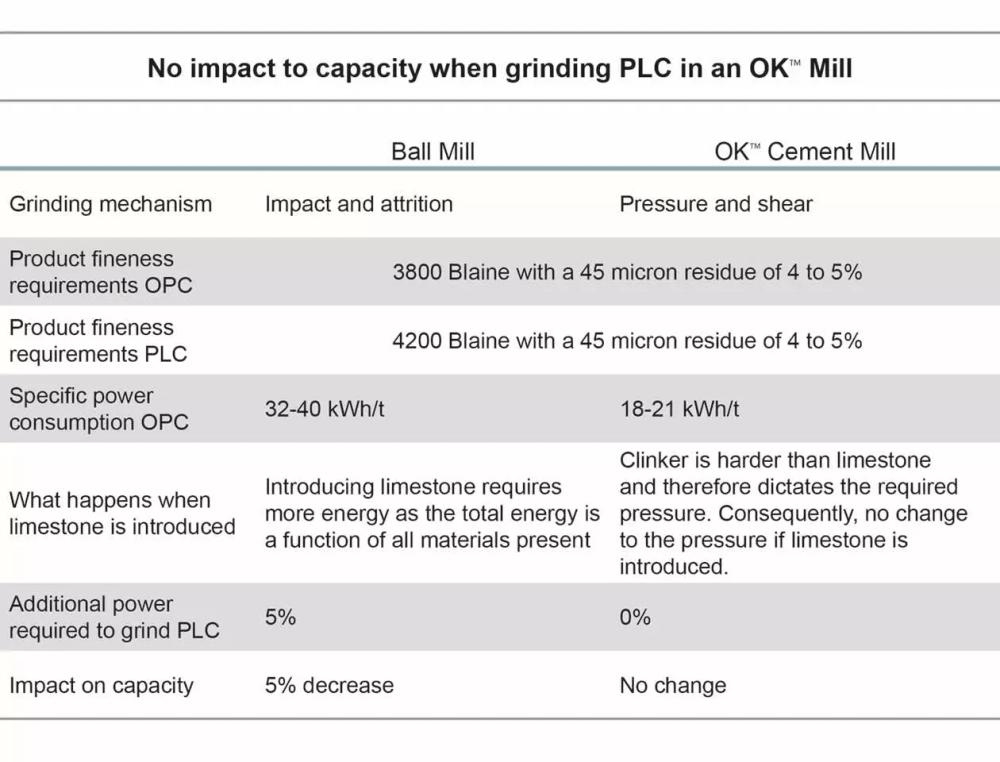

Limestone typically has approximately one quarter to one third of the grindability of clinker. Substituting limestone for clinker in a ball mill means there is a ~30% reduction in grindability for 15% of the total production, or ~5% reduction in power consumption or grindability.

When limestone is added to the mill, the product fineness must also be adjusted. As shown in the table, if the normal product fineness for OPC is 3800 Blaine and 4% residue on a 45 micron sieve, PLC would require an increase to ~4200 Blaine in order to achieve the same 45 micron residue. Otherwise at 3800 Blaine the 45 micron residue might be 6 – 8%. In a ball mill this increase in Blaine equates to an increase in overall power consumption of approximately 10%, which results in an equivalent decrease in capacity.

The net result of the change in grindability and the required fineness adjustment is a 5% net decrease in capacity.

Vertical Roller Mill

Because of the difference in grinding efficiency in ball mills vs VRMs there is less impact from adding softer material in VRMs. VRMs use pressure to grind, where ball mills use impact and attrition. And because a much higher pressure is used to grind clinker than limestone by itself, adding 15% limestone has a nearly negligible impact on the overall specific power consumption in the mill. This would allow for approximately a 10% increase in capacity.

Not all VRMs are the same. The OK™ Mill has a grinding profile specifically designed for cement grinding and the best performing separator for cement applications. Therefore, it handles these adjustments more easily than other VRM designs.

In the OK™ Cement Mill similar product fineness adjustments are required when adding limestone as with ball mills. The impact of fineness adjustment from 3800 Blaine to 4200 Blaine to achieve the same 45 micron product residue is approximately 10% increase in power consumption. Therefore, an OK Cement Mill can produce the same capacity of PLC as OPC.

VRMs also provide much greater flexibility to grind a number of different materials, to switch between different cement mixes, and to adjust to changing material characteristics – all while protecting quality. This is thanks to the greater operational control, which is further advanced by the digital capabilities of the more advanced VRMs, like the OK Mill, which can use ECS/ProcessExpert® control solution to optimise grinding, Online Condition Monitoring to reduce downtime, and a range of other digital tools to increase performance and reliability.

Furthermore, as the acceptance of blended cement grows and manufacturers consider other SCMs, it’s important also to note that drying is incorporated within the VRM’s operation, making it suitable for a wider variety of cement mixes. For example, we have a customer using the OK mill to grind 100% slag with raw feed containing more than 20% moisture to product moisture levels less than 1%. This wouldn’t be possible with a ball mill or roll press with ball mill circuit without adding additional flash drying equipment because they don’t have the drying capacity of the VRM. This level of flexibility is imperative to SCM adoption.

Learning the lessons from PLC

Another important lesson from the riotous success of PLC in the US is how quickly new cements can be adopted when there is the regulatory support and the consumer demand. The industry needs to take the momentum gained and run with it to explore other avenues for carbon reduction, such as the use of pozzolanic materials such as shales, calcined clay and reclaimed flyash stored in ponds.