article

Reliability Centred Maintenance (RCM)

We believe Reliability Centred Maintenance is an essential tool for an industry determined to increase sustainability. As cement plant operators come to understand the connection between equipment reliability and environmental impact, we expect more and more plants to undertake their own RCM implementation program.

Globally, the cement industry faces a number of challenges. Social, environmental and economic drivers are putting pressure on cement manufacturers to do more with less, making performance optimisation more important than ever. But achieving true optimisation is not just about choosing the most advanced equipment and operating it efficiently. Maintenance procedures are a significant contributor to performance, which is why preventive maintenance services have become such an important part of our business.

What is Reliability Centred Maintenance?

Reliability Centred Maintenance is a term that arose in the 1970s and was originally coined in relation to the airline industry. At that time, crashes were far more common – ~60 per million take-offs – and often it was found that faulty or worn equipment was to blame. Today the airline industry has upped its game and achieved a comparatively low rate of just 0.03 crashes per million take-offs. The Reliability Centred Maintenance approach is credited with helping them achieve this transformation. But what does it actually mean?

The clue is in the name. Reliability Centred Maintenance prioritises reliability – aka uptime. By reviewing – in our case – the cement plant’s operational context, we are able to establish levels of asset criticality, i.e. how important the equipment is to the plant’s operation. We then develop asset-specific maintenance strategies based on our understanding of the risks, and the type of maintenance that is needed to keep the equipment both operational and operating cost-effectively. The upshot is a strategy that takes a component-centric approach to maintenance, which typically falls into three categories:

- Proactive maintenance – Regularly scheduled procedures (e.g. daily, weekly, monthly)

- Condition-based maintenance – Responsive maintenance is performed based on data gathered through condition monitoring and inspections.

- Run-to-fault maintenance – For components that are allowed to fail because maintenance would have no impact on when or whether they fail.

Digitalization improves maintenance practices

Increasing levels of digitalization have enabled the evolution of maintenance practices. Where previously equipment may have been run to failure through lack of alternatives, modern condition monitoring equipment can give you advanced warning of potential problems before they have the chance to escalate, giving you the opportunity to carry out maintenance when it suits you. This increases the efficiency of the entire maintenance process, enabling you to properly plan and prepare for shutdowns – e.g. by ensuring the necessary parts are on site.

Compare this to the alternative. Failure occurs – perhaps suddenly and unexpectedly, potentially damaging other components in addition to the failed part – and the equipment is shut down. Unplanned outages are stressful and very expensive, as everyone rushes around trying to find the source of the problem and a quick resolution. Equipment can end up being out of operation for many weeks or even months while the new parts are sourced. In the meantime, productivity suffers and you could even end up losing customers to competitors who are in a position to fulfil orders while your equipment is shut down. You can see why Reliability Centred Maintenance is the more attractive option.

Factors which affect plant performance

Within the world of RCM we often talk about defining a plant’s operational context. Put simply, this means identifying the factors surrounding the plant and equipment that play a role in how well it performs. These include external and internal factors, as outlined below:

External factors:

- Weather conditions

- Environmental regulations

- Market conditions

- Government laws

- Community involvement/awareness

- High influence stakeholders

Internal factors:

- Age of equipment

- Condition of equipment

- Core function of the asset

- Design criteria of the asset

- Housekeeping standards

- KPIs

- Manpower skills and knowledge

- Organisational structure

- Certifications (ISO 90001, 140001, etc.)

This operational context serves as the foundation for your RCM program. An initial assessment or gap analysis of existing maintenance practices, safety conditions, etc. will also help determine which areas of the plant are currently underperforming.

How RCM works in practice

Implementing a Reliability Centred Maintenance approach is a process. Because cement manufacturing is made up of many intertwined systems, each of which involve myriad interlinking components, it can take a little bit of time to define the details. Typically, there are seven decision-making steps, as outlined below.

Critical equipment is selected for RCM analysis

The choice of equipment is based on its role and impact in the process, previous costs for repair and previous costs for preventive maintenance.

For every asset chosen, you need to define its inputs and outputs, and the function of the system within which it operates.

For example, the function of your conveyor belt is to transport materials. Its inputs are the materials it is transporting and the mechanical energy powering the belt. Its outputs are the materials at the other end. The electric motor powering the conveyor belt would fall under a different system.

List all the ways the system can fail to perform its function.

For example, if your conveyor belt broke, or was too slow. (We recently identified 9000 failure modes for a customer’s VRM – there can be a lot of scenarios to plan for!)

Identify the root causes for all these failure modes.

You will need to lean on the experts for this – especially if there are 9000 failure modes! For the conveyor belt example, root causes might be things like a lack of lubrication on the rollers, a bearing failure, or an insufficiently tight belt.

Explore how these failures would affect safety, operations and other equipment.

We use the Failure, Mode and Effects Analysis (FMEA) approach, which uses a series of questions such as ‘Does this failure mode have safety implications?’ and ‘Does this failure mode result in a full or partial outage of operations?’.

Choose a proactive maintenance tactic for each failure mode that could reasonably be expected to occur.

Condition-based maintenance makes sense where it is feasible to detect the onset of the failure mode; otherwise regularly scheduled preventive maintenance (i.e. based on time or usage) might be more appropriate. For failure modes that weren’t identified as critical, you may decide the run-to-failure approach is best. If you have identified a potential failure mode with no good condition-based or preventive maintenance option, a system redesign might be necessary to eliminate or reduce the impact of this scenario.

Once the agreed maintenance tactics have been put into practice, you can review the results and decide if you need to make any changes based on the additional information you gather.

The RCM approach is not static, but should be continually reviewed and renewed.

When working with a cement producer to implement an RCM approach, we use decision tree flow charts to guide the task selection process. We then bring in our experience with both the technology and the process to develop detailed maintenance plans and inspection routines. In this way we deliver a tailored maintenance program specific to your plant, your operational context, and your equipment.

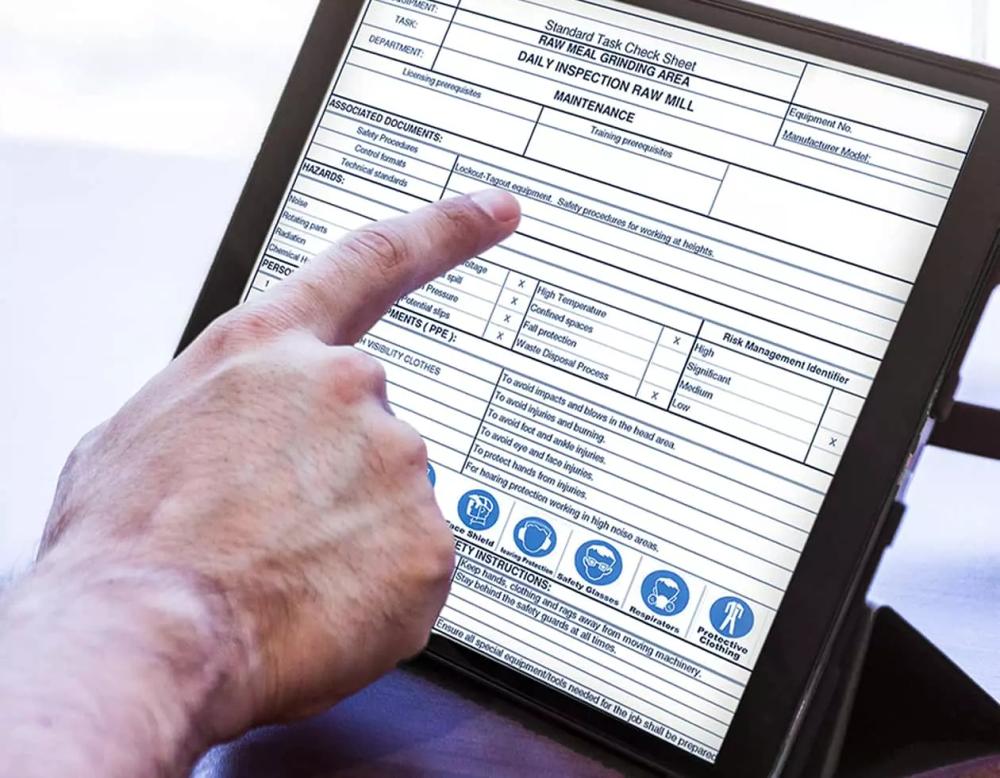

The result is task sheets and instruction guides, which include information on common practices such as calibration procedures, interpreting testing results, specific wear measurements, etc. This not only ensures you have everything you need to carry out your defined maintenance strategy, but that everyone is doing it in the same way. The maintenance program is also instrumental in defining future Capex strategies, since it helps you recognise where redesigns, rebuilds and high-value spare parts are necessary. General spare parts strategy is also fed by the RCM plan.

Investing in staff is critical to success

Just as the best equipment doesn’t guarantee you optimum performance, the best maintenance strategy can’t guarantee you absolute reliability. Success lies in the delivery of that strategy, which depends on the strength of your team. When we help a cement plant implement an RCM program, we also develop a training and mentoring plan for the team who will be carrying out the tasks we have identified. This training includes an introduction to RCM, what it is, how it is being applied, and why it is effective.

We also deliver theoretical and practical training on plant equipment, testing regimes, inspection methods, and so on, to give everyone the best possible foundation for future success. After the training, we run a mentoring program where our development people run through each of the maintenance routines with the plant teams responsible for executing the plan. This field-based period enables optimum knowledge transfer, and gives us all a chance to work out any kinks in the program.

Maintenance = optimisation

More and more, cement plants are recognising the value of maintenance to optimising plant performance, increasing efficiency and achieving greater sustainability. The results are impressive. One of our customers went from an availability factor of 71 – 86% to consistently greater than 90%, with resultant additional cement sales of more than US$2.5 million – all within four months of RCM implementation.

We believe Reliability Centred Maintenance is an essential tool for an industry determined to increase sustainability. We are keen to share our experience and expertise as part of our Mission Zero goals.

.png?w=1080&q=80&auto=format)