article

Services help pave the way to Net Zero in India

As the cement industry continues its journey towards net zero, FLSmidth Cement is focusing on optimization at every stage of the process to increase efficiency and, in turn, sustainability. We talked to Raveendran Chalil and Manoj Taneja to find out how service and sustainability are intertwined, and why performance optimization underpins the industry’s ambitious environmental targets.

What is the relationship between services and sustainability?

“Services help to improve plant performance,” says Raveendran Chalil, Head of Service Execution for FLSmidth Cement in India. “For example, through a proactive maintenance approach we can eliminate unplanned shutdowns and thus reduce the number of carbon-intensive kiln startups. And through the various optimization services we offer that improve energy efficiency, we’re reducing energy consumption. Services were traditionally viewed as a way to lower operating costs and maintain productivity, but I think now our customers recognise the link between improved plant performance and reduced environmental impact and that’s a core driver for plants with ambitious sustainability targets.”

Manoj Taneja, Country Head, FLSmidth Cement

How does proactive maintenance support sustainability?

“Historically, there was little choice but to wait for things to breakdown and then react,” says Manoj Taneja, Country Head, FLSmidth Cement. “But with new digital technologies it is far easier to take a proactive maintenance approach that reduces downtime and maintenance costs – and in turn improves energy efficiency. Even small improvements can make a significant contribution to CO2 targets. To support this, we’ve brought in online condition monitoring services across the flow sheet, which provide 24/7 condition monitoring of key equipment and alert the plant to potentially dangerous conditions, enabling them to act before failure occurs. We also have a range of Reliability Centered Maintenance services to help cement plants develop a robust, considered maintenance approach that could eliminate unplanned downtime, reduce overall downtime, and cut ongoing maintenance costs. All of this contributes to a lower carbon footprint by improving process stability.”

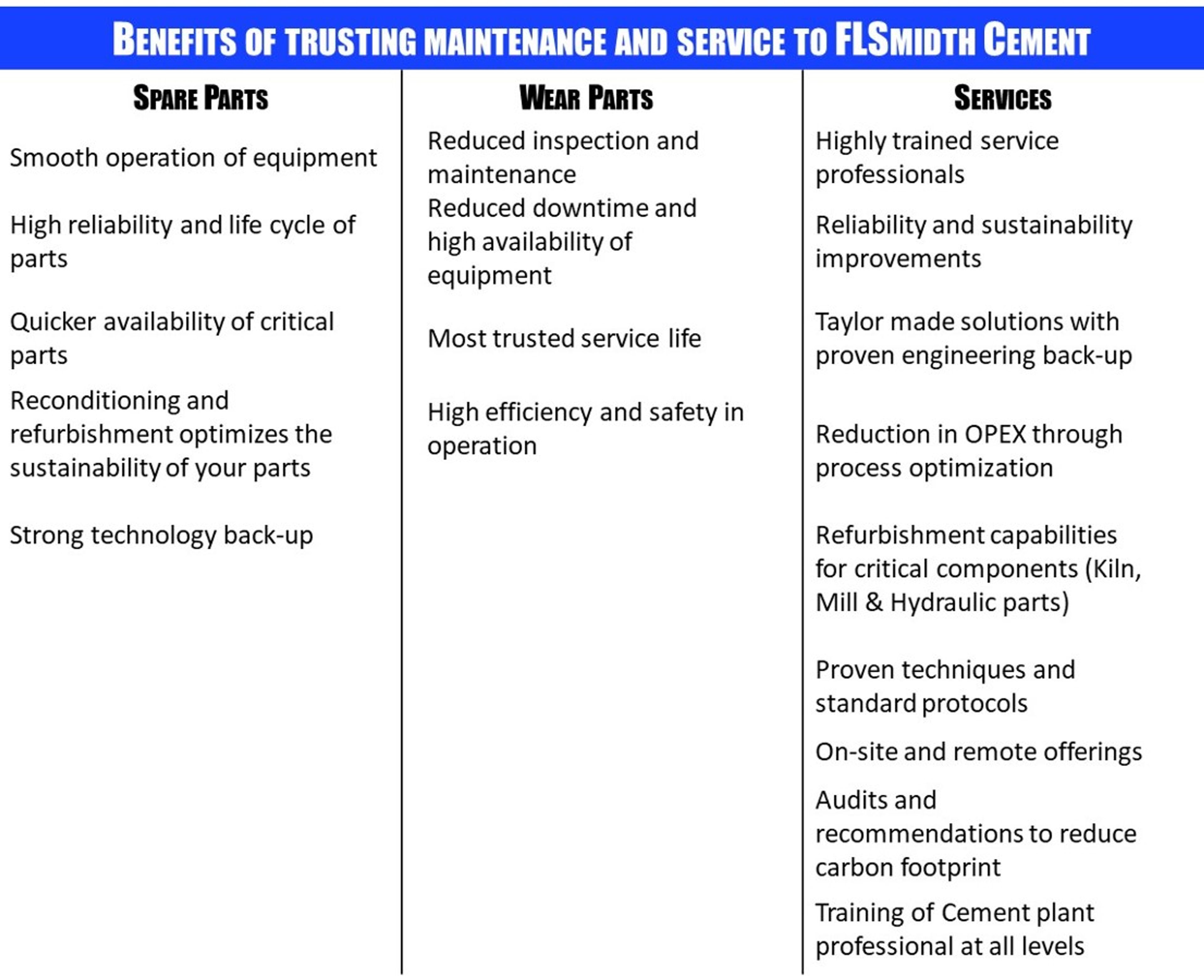

“One of the strengths of FLSmidth Cement is our global network,” adds Raveendran. “That means not only that we have experts worldwide who can, with remote service offerings, be on hand almost immediately to support with troubleshooting, etc. But we also have facilities holding our OEM quality wear and spare parts all over the world, so they are never far away when they are needed. Plus, we have the capability to recondition and refurbish old parts to extend their service life – all of which adds up to lower lead times, greater reliability and lower cost, and with a reduced environmental footprint.”

Can services optimize plant performance?

“Yes,” says Raveendran. “A sustainable cement process must do more with less. Our optimization services help plants find – and close – performance gaps. We perform audits both on specific areas of the process and on the entire plant, depending on what the customer requires. We can then help put these findings into action. Working together with digital technologies like ECS/ProcessExpert® advanced process control, these services help reduce energy and fuel consumption, while maximizing cement production. This enables plants to save money and reduce the carbon footprint of their end product.”

How else can services support environmental targets?

“The end goal is always to reduce the emissions intensity per ton of cement,” Manoj explains. “In addition to our focus on efficiency, we also work with plants to establish other pathways to lower carbon cement. This includes studies to determine the potential of supplementary cementitious materials (SCMs) that will enable to reduce the clinker content in cement, as well as use of alternative fuels to replace fossil fuels. We firmly believe that our services – alongside new innovations in equipment – will help the industry achieve its ambitious goals for 2030 and beyond.”

“Cement plants are faced with demanding goals and a heavy environmental burden. As an experienced technology and service provider, we are here to support our customers every step of the way. We share their ambitions and are just as committed as they are to reaching those goals,” says Raveendran.

%20VRM.jpg?w=3840&q=100&auto=format)