article

The How, What, and Why of Grinding SCMs

In recent decades, the cement industry has made great strides towards reducing its carbon emissions. But while the utilisation of alternative fuels is increasing and new technologies are driving efficiency in the cement manufacturing process, a sticking point remains: The calcination of limestone is the industry’s largest source of emissions. To address this, cement manufacturers must reduce the quantity of clinker in the mix and replace it with supplementary cementitious materials, or SCMs.

What, where and how much – SCM adoption worldwide

The adoption of SCMs varies widely depending on where you are in the world. In India and Brazil, for example, it is common to use fly ash and slag to reduce the clinker factor to as little as 65%. In the US, the clinker factor remains high at around 95%. Worldwide, according to the Climate Technology Centre & Network, the ‘average clinker/cement ratio is about 0.81, with the balance comprising gypsum and additives such as blast furnace slag, fly ash, and natural pozzolana.’₁ The UNEP-sponsored white paper ‘Eco-efficient cements: Potential economically viable solutions for a low-CO₂ cement-based materials industry’ suggests a reasonable worldwide average of 0.60 is achievable by 2050.₂

Availability of SCMs is certainly a factor, together with standards and regulations, which are more restrictive in some countries than others. But there is also a lot of uncertainty in the industry: Which materials are ‘best’? What is the most suitable grinding technology for SCMs? How easy is it to integrate new materials into existing plants?

With many decades’ experience grinding a wide range of different materials in vertical roller mills, ball mills and hydraulic roller presses, FLSmidth is in a position to share our knowhow to help the industry make strides in reducing its carbon footprint.

Types of SCM

SCMs can be naturally occurring materials, or arise as a by-product of other industrial processes. The Global Cement and Concrete Association (GCCA) groups SCMs according to how they harden₃: hydraulic SCMs harden in the presence of water (like Portland cement) and include granulated blast furnace slag (GBFS) and burnt oil shale. Pozzolanic materials require the additional presence of dissolved calcium hydroxide (Ca(OH)₂) – a by-product of the hydration of Portland cement – in order to harden. These include fly ash, silica fume, calcined clays, burnt rice husk and natural pozzolans. Hydraulic cements have a higher early age strength, while pozzolans continue to gain strength for a longer period, giving a higher long-term concrete strength. Both have been proven in construction applications. Limestone is not classified as either hydraulic or pozzolanic but also contributes to the hardening of concrete, putting it in an SCM category all of its own. Table 1 gives a general overview and some background information for the different SCM used in cement manufacture today.

Table 1. Common types of SCMs

Current examples of SCM adoption

Subcontinental India

India is a successful adopter of SCMs, with an average clinker factor of 0.71 in 2017. This is largely thanks to the introduction of standards for composite cements in 2015, which encouraged market adoption, as well as the widespread availability of fly ash from thermal power plants.

Portland Pozzolanic Cement (PPC) production in 2017 amounted to about 65% of the market, and the clinker factor of PPC was also improved from 0.68 in 2010 to 0.65 in 2017. Portland Slag Cement (PSC) makes up about 10% of the market and also reduced clinker content in that time from 0.55 to 0.40.₄ Meanwhile, Lafarge Holcim-owned ACC has achieved a clinker factor as low as 44% through the use of fly ash from power plants and slag from steel production.

Table 2. Cement production at Shah Cement in Bangladesh

In the Sub-Continental India region FLSmidth has supplied grinding systems with all types of mills. The most common grinding systems installed over the last 10 years are VRMs or HRP with ball mill in semi-finish arrangement. The number of VRMs installed for cement grinding trends higher due to better overall power efficiency and lower maintenance costs. One example is the Guinness World Record largest VRM for cement grinding at Shah Cement in Bangladesh. That mill regularly produces both PPC and PSC Cements as shown in Table 2.

Throughout Asia, a wide range of blended cements or Portland Composite Cements (PCC) are made encompassing many different additive materials including trass, which is very hard-to-grind overburden from the quarry. Stable and reliable operation has been proven in the OK mill even with this difficult material. Table 3 shows typical operation for an OK Mill grinding PCC with 71% clinker factor.

Table 3. Example of Portland Composite Cement production in Asia with an OK Mill

Brazil

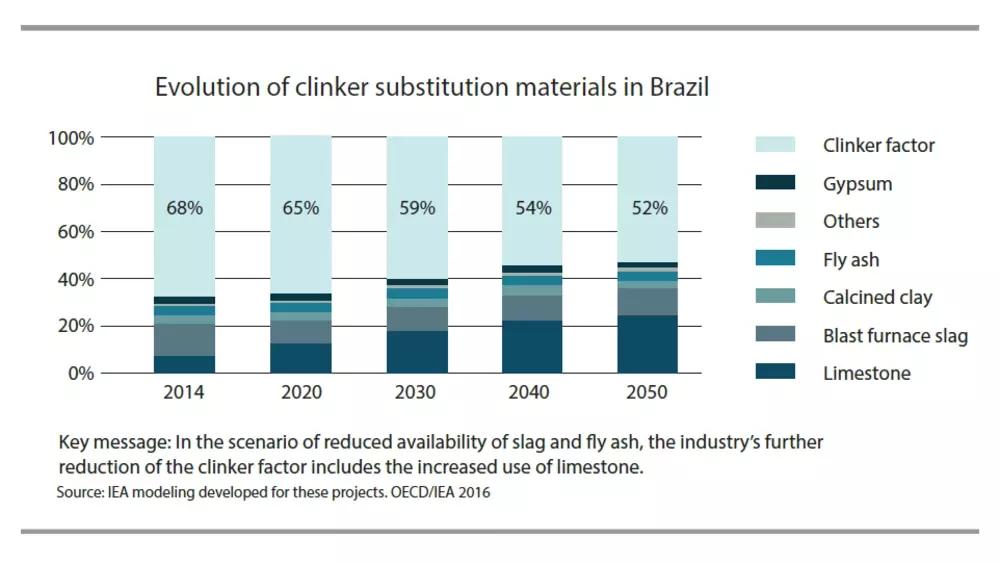

The Brazilian cement industry has a long history (more than 70 years) in the production of blended cements, with a nationwide average clinker-to-cement ratio below 70%.₅ In Brazil, the most widely used SCM is currently blast furnace slag from steel mills,₆ though calcined clay and fly ash are also in the mix. This balance is likely to change, however, as the country aims to achieve a significant reduction in the clinker quantity of its cement from current levels to 59% in 2030 and 52% in 2050.₇ Given that slag and fly ash availability will be unlikely to keep up with demand, the industry is looking to limestone filler and calcined clays to meet these targets.

Figure 1: Historic and future development plan of clinker substitution with SCM in Brazil.

In Brazil, the VRM has been the standard for new cement grinding for the last 10+ years, with OK Mills accounting for 30% of the country’s total annual cement production since 2015. This is due to the mill’s flexibility and efficiency. Some examples of OK Mills operating in Brazil can be seen in Tables 4 and 5.

Table 4. Example of composite pozzolan cement production in Brazil (72% Cl 14% fly ash 10% limestone 4% gypsum)

Table 5. Example of composite slag cement production in VRM and Ball Mill in Brazil (75 % clinker, 5 % gypsum, 15 % slag and 5% limestone)

United States

Use of SCMs in the US is considered as blended cement by the USGA₈. Blended cement refers to a finished blended cement product made at a cement plant or its terminals. In 2020 blended cement accounted for only 3.2% of total cement production. This low level of SCM use is largely because US cement plants generally follow the ASTM C-150 Standard (American Society for Testing and Materials) which defines a limit of 5% limestone (which in practice often translates to 3%).

However, the 3.2% doesn’t include the blended cement produced at concrete plants. In fact, the ready-mix industry blends their products to a much more diverse standard, often introducing various additives and even recycled concrete to accommodate the needs of their local markets and specific applications. This, together with experience with masonry cement (1% of annual cement production, with as much as 70% limestone addition), and Type III cement (95% clinker, 5% gypsum but with a product fineness of +5000 Blaine₉) – both suitable for production in VRMs – should give the industry and end users the confidence that different ‘recipes’ can be successful, and that handling a wide range of product characteristics is perfectly possible as expanded cement standards are adopted.

In the future, it is hoped that end users will specify for performance rather than recipe when buying cement. This will give cement and concrete companies greater flexibility with their blends, and will make it easier to reduce the clinker factor. In the meantime, Portland Limestone Cement₁₀ has been championed by the Portland Cement Association as a lower-carbon alternative to OPC, utilising limestone filler to reduce the clinker content and thus the environmental impact of cement by 10%.

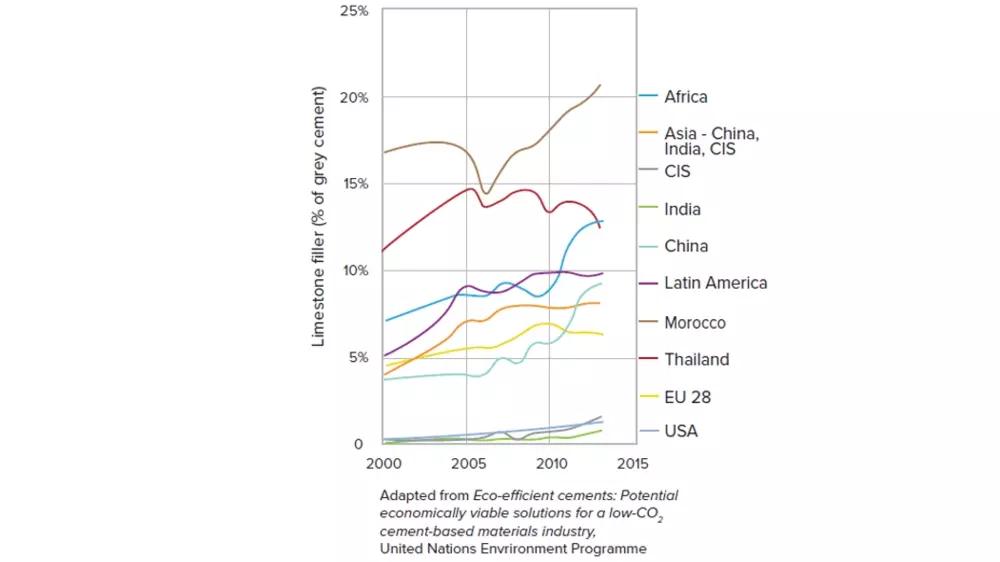

The UNEP-sponsored white paper ‘Eco-efficient cements: Potential economically viable solutions for a low-CO₂ cement-based materials industry’ referenced earlier in this article also includes references for limestone addition to Portland Cement in various markets around the world. Figure 2, shows the percentage of limestone substitution in grey cement by country from 2000 through 2015. The wide range of variation from countries with higher substitution levels to those with the lowest, including the United States, demonstrates the potential improvement with further adoption of Portland Limestone Cement.

Figure 2: Average Limestone Substitution in Various Regions.

How – which mills are best for SCMs?

The grinding operation is critical in order to achieve the necessary particle size distribution for the successful use of SCMs. Some materials can be ground together with the rest of your cement mix (so-called ‘intergrinding), while others may benefit from a separate grinding operation. Likewise, water demand (to increase workability) can present another sustainability concern that requires additional process treatments – such as chemical admixtures – to address.

In terms of mill type, the answer is almost always vertical roller mills (VRMs). Over the last few decades the industry has been gradually moving towards the use of VRMs for both raw and cement grinding, due largely to the reduced energy consumption compared to ball mills: a saving of between 30 and 50%. This transition will prove crucial as the adoption of SCMs increases, from a practical as well as economic and environmental perspective. VRMs provide much greater flexibility to grind a number of different materials, to switch between different cement mixes, and to adjust to changing material characteristics – all while protecting quality.

For example, we have a customer using the OK mill to grind 100% slag with raw feed containing more than 20% moisture to product moisture levels less than 1%. This wouldn’t be possible with a ball mill or roll press with ball mill circuit without adding additional flash drying equipment because they don’t have the drying capacity of the VRM. This level of flexibility is imperative to SCM adoption.

Figure 3: An OK Mill installed for blended cement production. The pneumatic conveying system for feeding fly ash is seen on the front of the mill.Ultimately, product quality is defined by cement strength development and setting times. To achieve the best result, you need optimal particle size distribution and dehydration of the gypsum within the cement. And for that, the precise operational controls of the VRM are a clear advantage over other mill types, enabling you to optimize the system’s temperature profile, mill airflow, separator speed and grinding pressure for optimum efficiency and productivity.

Why use VRMs?

- With greater control over the operational variables, it is much easier to adapt to different material types.

- Due to the short residence time, changing from one product mix to another is a relatively quick and simple process compared to ball mills.

- Drying is incorporated and efficient.

To put it bluntly, if the cement industry truly hopes to achieve net zero carbon by 2050, VRMs are the only way to get there for cement grinding.

Digital makes it easier

Digital technologies simplify the adoption of SCMs and increase the potential for greater clinker replacement in the future. The capability of digital technologies is continually advancing – giving even more reason for optimism about the future of SCMS – but even now there are a number of digital tools that optimise performance and productivity:

- Process Expert control solutions give operators greater control over their mill operating parameters. Advanced automation enables real-time adjustments to optimize performance and ensure maximum efficiency.

- Sensors continually monitor mill operation, enabling you to see any drop in stability as it happens and react swiftly. This is helpful to avoid a decline in performance as you switch from one material to another.

- Automated laboratories enable optimum quality control throughout the process, giving you the opportunity to adjust mill feed in real-time.

- Condition monitoring services and remote service support give you 24/7 access to expert assistance, so if there are any problems they don’t have the opportunity to escalate.

Predictive maintenance sustains performance

The use of a wider range of materials typically has a negative impact on wear rates and mill stability, which can lead to a higher maintenance burden. However, that doesn’t have to be the case. With tools such as online condition monitoring it has become much easier to be proactive about maintenance to the extent that you can eliminate unexpected downtime and considerably reduce your maintenance budget.

For example, by monitoring equipment performance, it is possible to develop a predictive maintenance program that is based on real-time operating data. You can identify how and why wear is occurring, prepare the necessary response (e.g. order in spare parts, plan repair work around peak operating times), and carry out the right repairs at the right time for minimal loss of productivity. Ultimately, a predictive maintenance approach is the best way to guard against the mechanical failures and rising maintenance costs that would otherwise be inherent to adopting these new, harder to grind materials.

Conclusion

As the cement industry works to reduce its carbon footprint, investments have to be made in future-proof technologies capable of adapting to changing cement mixes and regulatory requirements. In the grinding process, cement manufacturers need a flexible, efficient system that is operated and maintained in an optimal manner. With the latest VRM technologies, advanced digital offerings and condition monitoring services, FLSmidth believes the industry is ready to achieve more widespread use of SCMs and achieve its carbon reduction goals.

This article was first published in World Cement , May 2021.

Notes

[1 ] https://www.ctc-n.org/technologies/clinker-replacement

[2] https://wedocs.unep.org/bitstream/handle/20.500.11822/25281/eco_efficient_cements.pdf

[3] https://gccassociation.org/sustainability-innovation/health-safety-cement-innovation/clinker-substitutes/

[4] https://docs.wbcsd.org/2018/11/WBCSD_CSI_India_Review.pdf

[5] Jared Weston, “Brazil gives OK to VRM”, International Cement Review, 20 June 2016

[6] https://www.mckinsey.com/~/media/mckinsey/dotcom/client_service/infrastructure/pdfs/pathways_low_carbon_economy_brazil.ashx

[7] http://snic.org.br/assets/pdf/roadmap/roadmap-tecnologico-do-cimento-brasil.pdf

[8] https://pubs.usgs.gov/of/2005/1152/2005-1152.pdf p.10

[9] We have experience and references for OK Mills making TYPE III cement as part of standard production schedule along with OPC. The proven ability to make such a wide range of product fineness is reassuring when it comes to future product that are likely to have similar requirements.

[10] https://www.greenercement.com/