article

The reliability fallacy: The key to sustainable cement production

What does your maintenance team want you to know about reliability, but is afraid to tell you? Jose Gil, FLSmidth, explains. Ask anyone working at a cement plant and all would agree that reliability – of equipment, of the process, of production output, of product quality – is critical. FLSmidth would also agree. In fact, the company even has Reliability Centred Maintenance (RCM) service specifically designed to help cement plants prioritise reliability. Ask who is responsible for reliability and they would probably all point to the maintenance team. And here, FLSmidth would disagree.

It is true that the maintenance team is at the frontline of delivering reliable performance: the RCM approach is predicated on that fact. But unless the other business functions – from management through to sales and production – also consider reliability in their activities, reliability can become very difficult, if not impossible, for the maintenance team to deliver.

What is reliability?

One of the problems that FLSmidth often encounters when called in to perform reliability studies is a fundamental misunderstanding of what reliability is, how it is achieved – and how it is lost. So, before exploring any further, let’s take a step back and consider what reliability actually is.

One definition of reliability is that a particular piece equipment simply runs without failures or faults that result in unplanned downtime. However, we would argue this is short-sighted because it does not take into account how well that equipment is running, simply that it is running at the moment. In this scenario, a plant that meets its annual production target, but has to run 10% longer to do so than its performance specifications indicate it should, or consumes 10% more energy in the process, is still reliable.

Is this reliability? No. FLSmidth believes reliable equipment not only runs continuously without unplanned downtime but performs well when doing so. Achieving this is more complicated – but much more profitable in the long term. Several key factors go into it:

- Setting production targets that are deliverable by the equipment you have available.

- Operating the equipment within realistic limits.

- Developing a proactive, preventative and properly funded maintenance strategy.

- Ensuring the right people have the right skills, time and understanding to deliver that maintenance strategy.

The quest for reliability thus begins not with the maintenance team but in the upper echelons of company management.

Don’t forget the maintenance team

The goal of all cement manufacturers is to produce more cement at less cost. In a hot market, there is even more pressure to do so. Seeing a chance to cash-in on rising demand, the management team calls for a 10% increase in production. The sales team immediately jumps on this and starts to sell that extra production. The plant operations team is now on the backfoot and pushes the equipment to get every possible tonne out of it, even if it means operating for longer, at higher load, than the equipment was designed for.

Who is missing from this picture? The maintenance team! This relatively small group of people are then suddenly tasked with delivering reliability in a scenario where the equipment is being pushed too hard and too long, not only increasing the risk of unexpected failure, but also cutting into the time available for maintenance. As a result, inspections are performed only perfunctorily, or skipped altogether. Inevitably, at some point, something breaks.

The key point here: if management does not understand the impact they have on reliability, it becomes very difficult – if not impossible – for those below them to deliver it. Targets should always consider the ability of the equipment and personnel to meet them, otherwise any short-term gains in production will likely be outweighed by the long-term cost in equipment wear and replacement. This long-term cost will threaten a plant’s ability to meet commitments to customers and thus damage its competitive position. It may also create a highly stressful work environment that pitches the plant operations team against the maintenance team.

The position of management will also feed down to the sales team. In an extreme example, FLSmidth experienced a sales team telling plant personnel when they could and could not stop for maintenance in order to keep production on top of orders. This may not be common, but when sales volume is set over and above all other considerations, reliability will fall by the wayside.

Spend to save

If it is important the management team understands reliability, the same is true of finance. It is all well and good to develop an effective RCM strategy on paper, but unless those responsible for approving expenditure and procurement also buy into it, it will remain on paper. This can be a difficult conversation to have, as maintenance is too often seen as a cost, rather than an investment with a return. But that is what reliability-centred maintenance is: an investment. True reliability will ultimately deliver a return in terms of higher uptime, prolonged life of parts and equipment, and improved productivity. The cost is thus far outweighed by the long-term gain.

The same principals also apply to having the correct personnel in place to implement an RCM plan. If the skills are not available to effectively implement reliability-centred maintenance, it will not happen. Simple as that. These skills should be nurtured and developed – and should not be bogged down by other unrelated tasks. Too often are reliability engineers so distracted by other responsibilities that they simply do not have the time to spend on the essentials of their job.

This should demonstrate that reliability is as much the responsibility of those ‘soft’ job functions in management, sales, finance, and HR. Without an understanding of what reliability is and needs within these roles, it becomes so much more difficult to deliver at the plant level.

The reactive maintenance trap

Putting a plant’s ability to meet production targets – to ‘achieve’ reliability – into the hands of one relatively small team of maintenance workers is the common mistake made when reliability is misunderstood within the wider corporate environment. It is also the reason that so many plants end up adopting a reactive maintenance approach, stuck with the cost burden of unexpected downtime because they were so busy chasing production that they did not ever give reliability a chance.

In a reactive approach to maintenance, a plant waits too long to fix problems, trying to eke out as much production as possible, even if this taking longer and costing more to achieve. Worse: problems may not even be identified until it is too late because the maintenance team does not have the time to make proper inspections. Data collection and analysis is also neglected because who has the time to do that? Ultimately, it becomes impossible to catch up on all the missed maintenance tasks, so they go undone.

This reactive maintenance trap is one that plants around the world have fallen into. It is an understandable trap to fall into, but there is a better way.

Reliability centred maintenance (RCM)

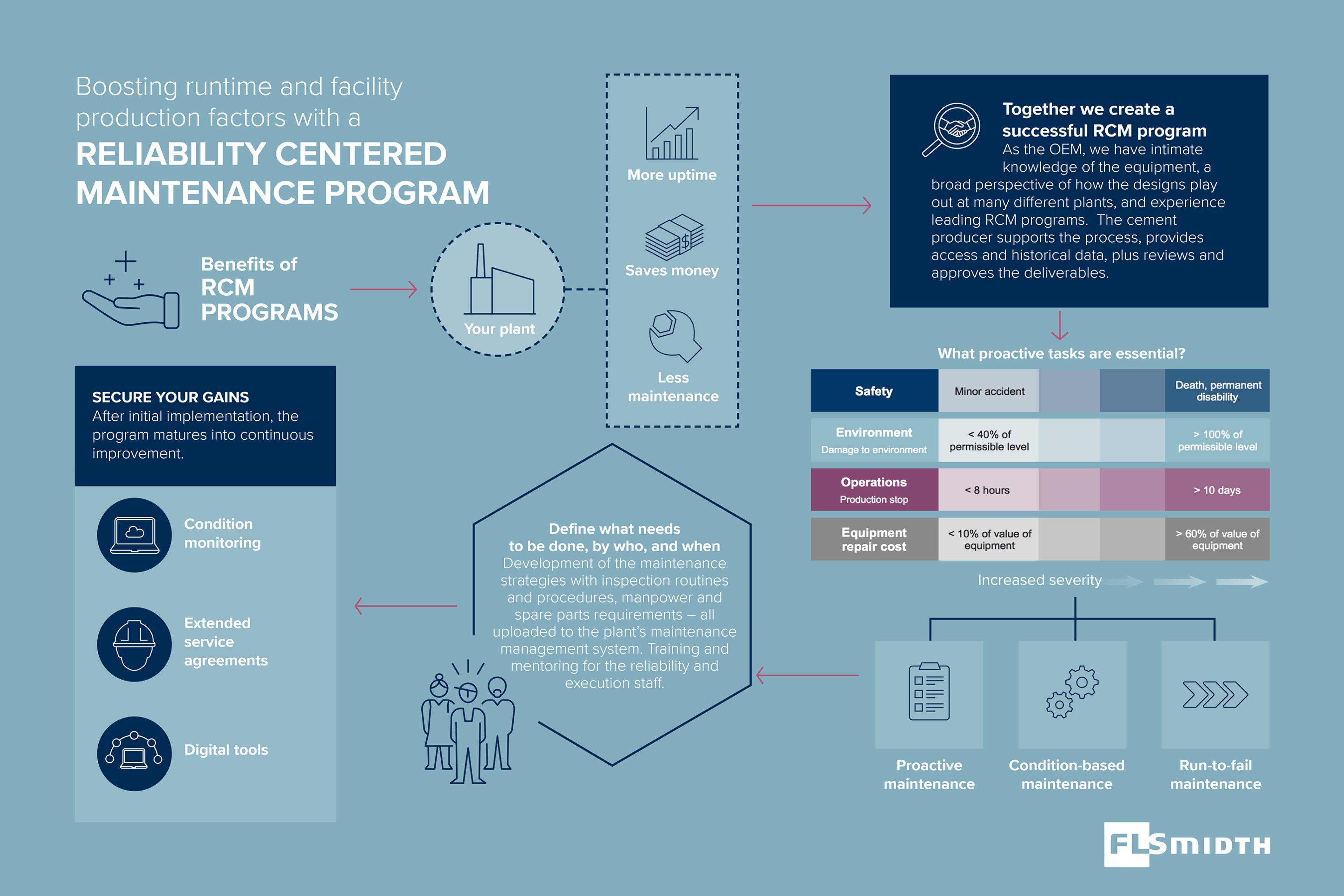

RCM is term that has been around for half a century. Coined in the airline industry in the 1970s, it is credited with reducing crash rates from about 60 per million take-offs to about 0.03 per million take-offs today. The approach involves establishing levels of asset criticality within a specific operating context (in this case, that of the cement plant). Asset-specific maintenance strategies are then developed based firstly on an understanding of the risk that the failure of the asset poses to plant operations, and then on the type of maintenance needed to keep the equipment operational and operating cost effectively.

The upshot is a strategy that takes a component-centric approach to maintenance, which typically falls into three categories:

- Proactive maintenance: regularly scheduled procedures (e.g. daily, weekly, monthly).

- Condition-based maintenance: responsive maintenance performed based on data gathered through condition monitoring and inspections.

- Run-to-fault maintenance for components that are allowed to fail because maintenance would have no impact on when or whether they fail.

A final note about digitalisation: when first developed by the airline industry, digital technology was basic. Modern digital solutions are exponentially more powerful and have delivered a revolution in what RCM can achieve. Where previously equipment may have been run to failure through lack of alternatives, modern online condition monitoring systems now provide advanced warning of potential problems before they have the chance to escalate. This increases the efficiency of the entire maintenance process, enabling plants to predict when maintenance will be required, and thus to properly plan and prepare for shutdowns, e.g. by ensuring the necessary parts are on site.

Other traps that make reliability difficult to achieve

The first of these has been touched on earlier: never underestimate the importance of inspections. These are the foundation for any effective maintenance strategy, but they are among the first things to go when a maintenance team is time-strapped and under pressure to deliver production at any cost. Too often have FLSmidth personnel visited a plant only to find parts that should have been regularly inspected sitting under a pile of dust.

The other trap relates to knowledge and skills. There is a global lack of talent that is affecting all of the heavy industries. Cement companies are therefore not only in competition with themselves but with a whole range of other sectors when it comes to recruiting and retaining talent. As the example from one plant shows, this can play out in dramatic fashion: When another facility – not a cement plant – opened up next door, it poached many of the cement plant’s most skilled people. Such loss of talent makes reliability almost impossible to maintain – and true enough, when FLSmidth arrived, the cement plant was performing well below its potential.

People are not easily replaceable. For the good of reliability, it is important that cement companies do as much as they can to hold on to skilled people. But to mitigate the risk posed by staff turnover, it is also important to ensure knowledge is held in common and not only by one expert or champion.

Reliability is everyone’s responsibility If everyone agrees that reliability is critical, it is only fair – no, essential – that it is everyone’s responsibility to see it achieved. That means setting targets that are informed by reliability; providing the investment in people and programmes to support reliability; planning maintenance to deliver reliability and not just react to problems; and preparing your people to understand and achieve reliability. This is where money should be spent if a plant wants to escape the traps and deliver sustainable productivity. It is time to stop pointing at the maintenance team: it is everyone’s job.

Five tips to increase reliability

1. Do not neglect inspections. If you want to understand equipment condition, you need to look at it, monitor it, and analyse it.

2. Give your technical people the time to do their jobs. If they are being pulled away from technical work to do other things, you are undermining their ability to help you achieve targeted productivity.

3. Shadow contractors and suppliers, so that when they leave the plant, their knowledge stays with you. See every site visit as an opportunity to learn from their experience.

4. Invest in a preventive maintenance strategy, and stick to it. Prevention really is better than cure.

5. Productivity ‘at any cost’ will end up costing a lot. Give your plant people the freedom to tell you what they need in order to get the most from your plant.