article

VENTOMATIC® Rotary Packer Upgrade in Turkey

Votorantim Cimentos' Hasanoglan Plant in Turkey has a capacity of 2800 tpd of clinker and 1 million tpa of cement, all destined for the local market. The plant was operating an old FLSmidth mechanical packer with a capacity of 40 tph. Though the equipment had served them well, it was no longer meeting their needs in terms of productivity. Moreover, newer VENTOMATIC® packing technology could offer a more environmentally friendly dust-free performance and greater weighing accuracy.

With this in mind, the plant undertook a modernization project in 2021, and chose to partner with us once again.

How automation helps packing plants

Automated packing technology provides a number of benefits. You can reduce manpower, which – of course – increases personnel safety. The reduced manual intervention also reduces waste and improves precision, contributing to a much cleaner environment. Moreover, greater weighing accuracy ensures maximum value for both the cement producer and their customers.

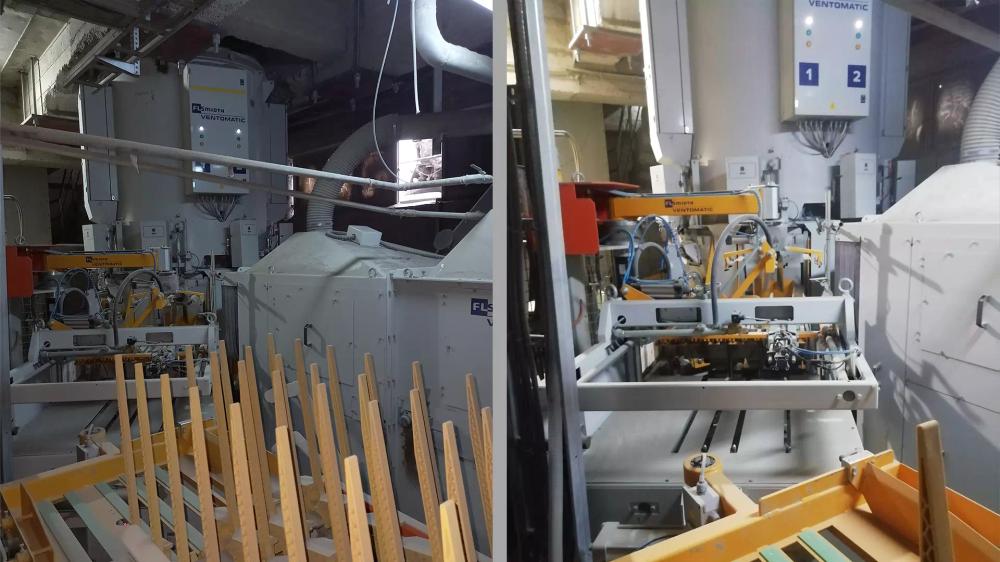

One of the reasons Votorantim Cimentos decided to renew their partnership with us on this project was our ability to create a bespoke packing plant layout that fits to their existing building. Our scope of supply for this project includes an 8-spout GIROMAT® EVO Rotary Packer, an INFILROT® BU Bag Applicator and VENTOSORT™ Bag Treating System.

BORA MUSLULAR, PLANT GENERAL MANAGER Votorantim Cimentos Hasanoglan Plant

Accurate and efficient rotary packer for cement

The rotary packer is one of our latest innovations. Its compact and modular design is both flexible and expandable, so you can employ up to 16 spouts for an output up to 4800 – 5000 50 kg bags per hour or 5300 – 5600 25 kg bags per hour. The GIROMAT® EVO packer is designed for bagging cement and other building material . The main features are:

- Impeller or fluidizing (air type) filling technology, to be chosen according to product.

- Bag clamping device for glued and stitched bags; suitable for various bag construction materials.

- Rapid discharge for quick product change-over.

- Bag sealing system based on ultrasonic technology.

For easy installation, VENTOMATIC® packers are composed of a number of preassembled modules, all of which are prepared and tested prior to delivery. These modules are quickly and easily mounted on the central tank of the packer during installation. In fact, the entire installation is very simple. The pneumatic connector plugs and electric rapid connectors are numbered so it’s clear exactly what fits where. This modular design enables you to put the packer into service with a reduced number of bag filling units. When you need to increase production, you simply add more filling units. At the Hasanoglan Plant, the new packer is capable of packing at a rate of 120 tph, but will begin by operating at 60 tph.

High capacity packing plants need robotic bag applicators.

At the heart of the empty bag handling operation is the automatic bag applicator, which is designed for handling both glued and stitched bags manufactured in paper, plastic, woven polypropylene or other similar materials. The INFILROT® BU bag applicator can handle up to 3000 bags/hour with reliability above 99.5%. It is highly flexible, able to switch between different material types, changing bag dimensions, and varying bag qualities without difficulty.

BORA MUSLULAR, PLANT GENERAL MANAGER Votorantim Cimentos Hasanoglan Plant

To ensure optimum ease of use, the equipment is operated by intuitive touch screen panels and IPC based technology. Operators are able manage machine alarms or to easily change settings such as dynamic weigh calibration directly from the control panel.

Successful outcome

The packing cement plant upgrade at Hasanoglan was contracted in October 2020, started in May 2021 and completed in June 2021. This swift project has been an immediate success – and one that the company plans to replicate at other sites in the near future.

We are very happy with the performance of the installed equipment and look forward to all the benefits it will bring our plant in the near and long-term,says Mr. Muslular, Plant General Manager of Votorantim Cimentos Hasanoglan Plant.