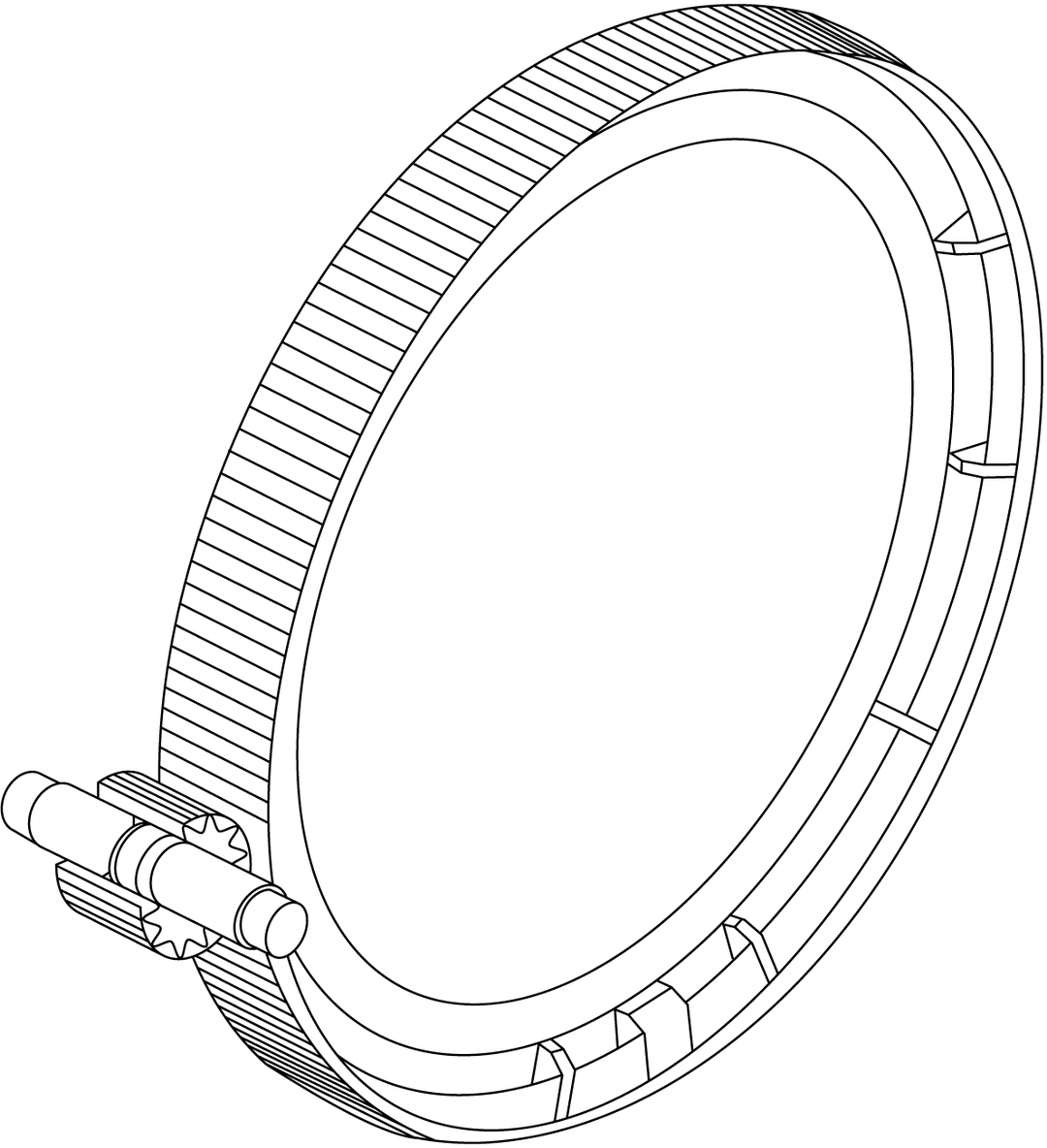

Keep your mill or kiln up and running with our heavy-duty girth gears

Our girth gears let you get the best from your mill or kiln

Our comprehensive expertise in forged gear ring technology comes from our more than 50 years of experience, as well as our collaborations with leading mill suppliers and technical universities. As a member of the American Gear Manufacturers Association (AGMA), we are actively involved in defining the standards for gear-rating calculations, service factors and other design standards. We continuously invest in technology and knowledge – along with steadily strengthening our network of partners. Over 1,000 girth gears are in service around the world – delivering optimal reliability for the cement and mineral industries. Applications for our girth gears also extend into the chemical processing and ceramic industries, food processing and pulp and paper.

Smart manufacturing creates durable, fit-for-purpose girth gears

Long-lasting, heavy-duty girth gears

Expert customisations

No risk of inclusions and other irregularities

The strength of our heavy-duty girth gears comes from the strength of our source materials and manufacturing process. We use fabricated steel, forged rings, rolled plates and ductile (nodular) cast iron to ensure the smooth operations for your mill or kiln. The continuous investment in our modern machine shops guarantees state-of-the-art girth gear production, in a wide-range of sizing: External gears: Maximum diameter: 11,200 mm; Face width: 1,250 mm; Maximum module: 45 by hobbing Internal gears: Maximum diameter: 6,500 mm; Face width: 400 mm; Maximum module: 25.4 The precision and quality of the girth gear manufacturing process ensures accurate alignment – resulting in heavy-duty gears that keep your comminution equipment running smoothly now and in the future.