14th Nov 2024

webinar

Next generation of ECS/ProcessExpert® (PXP) solutionV9

Pioneering Next-Generation Cement Process Optimization with ECS/ProcessExpert V9

In today's cement manufacturing environment, producers face increasing pressure to reduce energy consumption while managing operational disruptions and meeting stringent sustainability targets. Traditional process control systems struggle with cement's inherently complex, non-linear nature, creating challenges in maintaining consistent quality while maximizing efficiency.

FLSmidth's ECS/ProcessExpert V9 evolution delivers breakthrough capabilities that transform how cement plants operate, providing measurable performance improvements across all critical metrics.

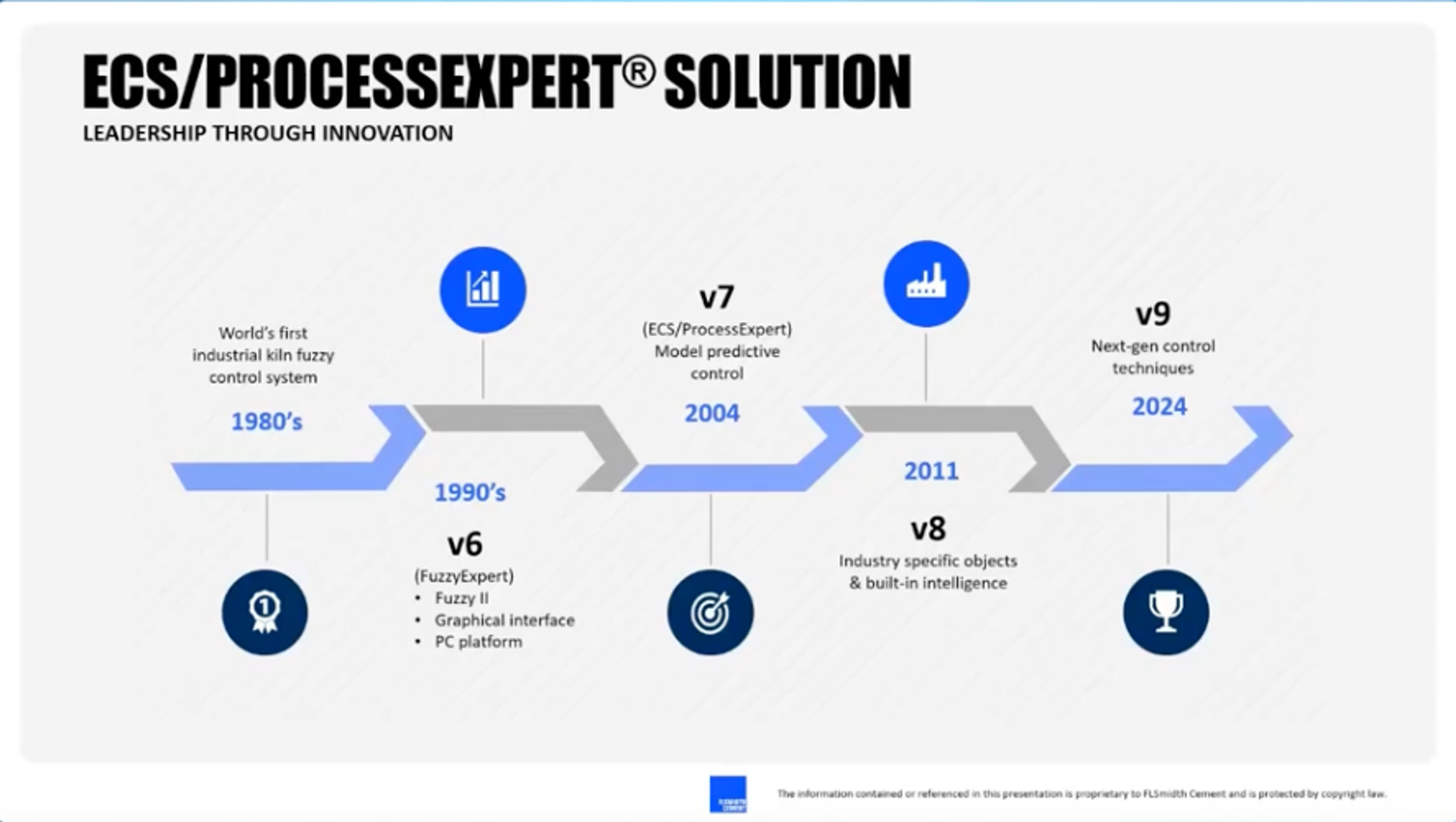

Building on five decades of industry leadership, ProcessExpert V9 introduces self-adaptive controllers that dynamically respond to changing process conditions without requiring multiple static models. This technology enables cement producers to achieve long-term process stability, reduce variability, increase alternative fuel usage, and deliver implementation consistency—all while significantly reducing commissioning time.

Access the full webinar to discover how the latest advances in cement process optimization technology can transform your operation's performance, profitability, and environmental footprint.

Featured Expert:

Dinesh Kumar Sampath, Global Product Manager for Optimization at FLSmidth Cement, brings 18 years of industry experience including specialized expertise in advanced process control implementation across global cement operations.

Key Insights Covered:

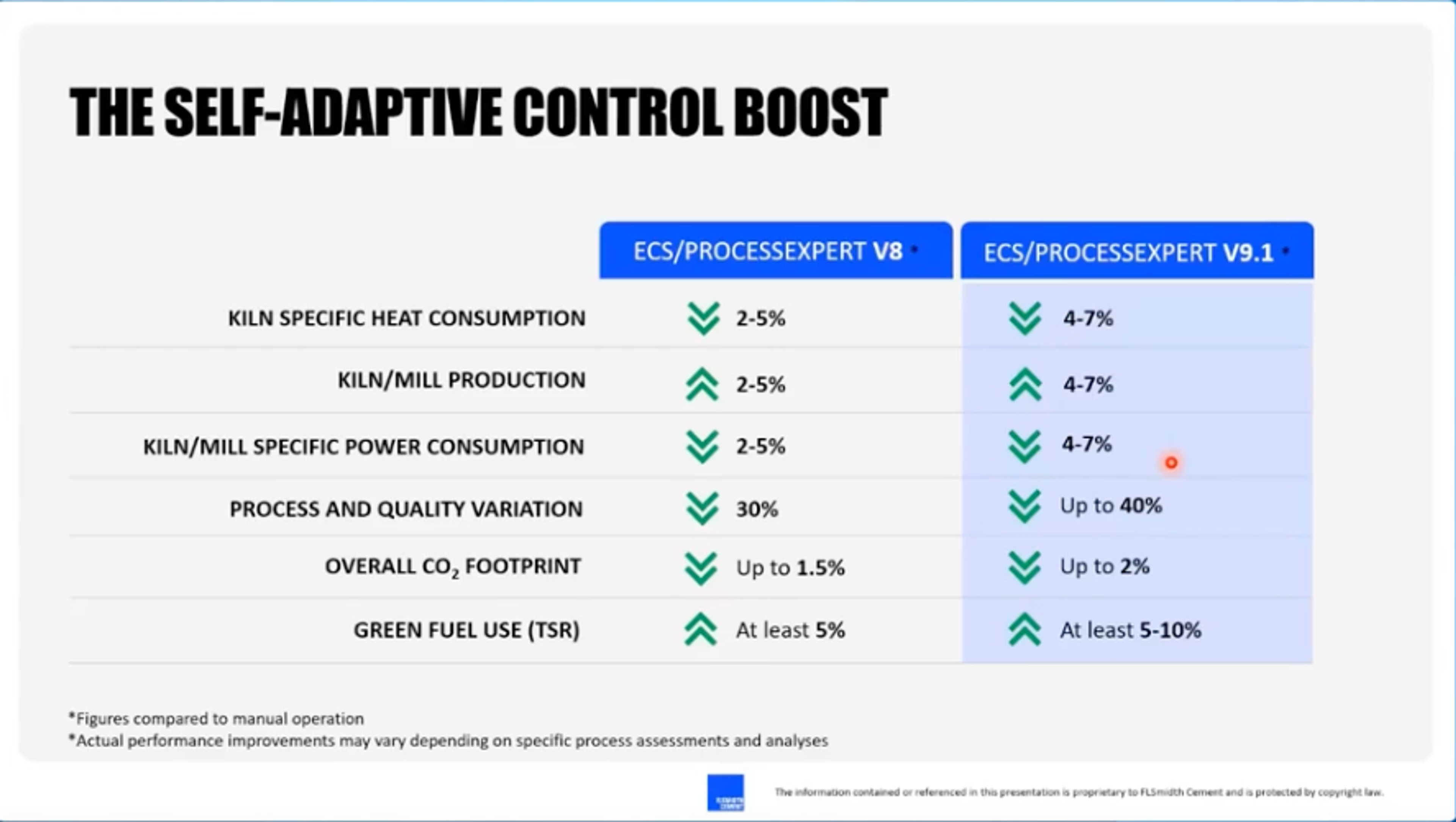

- Advanced self-adaptive controllers delivering 2-3% additional performance improvement over previous versions (7-8% total versus manual operation)

- Enterprise-level PXP Insights with cloud-based benchmarking capabilities for multi-plant operations

- Control Loop Performance Monitoring (CLPM) for rapid identification of underperforming control loops

- Flexible implementation options including subscription-based licensing with integrated service agreements

Explore how FLSmidth's ProcessExpert V9 can drive significant operational improvements at your cement plant by viewing the complete webinar recording.

- Dinesh Kumar Sampath, Global Product Manager for Optimization, FLSmidth Cement

Key Advancements in ECS/ProcessExpert® (PXP)V9 Evolution

ECS/ProcessExpert V9 represents the latest evolution in cement process control technology, addressing key operational challenges through intelligent automation and enhanced analytics capabilities.

Revolutionary Self-Adaptive Control Technology

- Adapts dynamically to changing process conditions without requiring multiple controllers

- Delivers 2-3% additional performance improvement over previous versions (7-8% versus manual operation)

- Increases process stability while reducing commissioning and optimization time

The self-adaptive controller represents a significant technological advancement in cement process control, allowing plants to maintain optimal performance even during process disturbances. Unlike traditional static models, this controller continuously adjusts parameters in real-time, leading to unprecedented stability and efficiency.

Enhanced Process Stability and Quality Consistency

- Reduces standard deviation in quality parameters by up to 40% compared to manual operation

- Enables increased alternative fuel usage (16-17% demonstrated at implementation sites)

- Improves clinker quality, potentially enabling reduced clinker factor in final cement

Process stability is a critical factor in cement production that directly impacts both operational efficiency and product quality. ECS/ProcessExpert V9's enhanced stability management delivers measurable improvements in quality consistency while simultaneously creating opportunities for sustainability enhancements through increased alternative fuel usage.

Advanced Analytics and Performance Benchmarking

- Enterprise-level cloud-based dashboards enable cross-plant performance comparison

- Control Loop Performance Monitoring (CLPM) identifies underperforming control loops

- Sustainability dashboards quantify CO₂ savings achieved through optimization

The analytics capabilities in version 9 transform how cement producers monitor, benchmark, and improve their operations. By providing powerful visualization and comparison tools, plant managers can quickly identify opportunities for improvement across their operations and quantify the environmental impact of process optimizations.

Subscription-Based Implementation Model

- Lower initial investment compared to perpetual licensing

- Regular updates ensure access to the latest features and performance improvements

- Includes comprehensive service agreement with proactive support

The evolution to a subscription-based implementation model represents a strategic shift that ensures plants maintain access to continuously improving technology. This approach eliminates large capital expenditures while providing ongoing expert support and technology updates, helping cement producers stay at the forefront of process optimization.

Advanced Process Control Redefining Cement Operation Performance

Today's cement producers face intensifying pressure to simultaneously improve productivity, quality, and sustainability metrics in an increasingly complex manufacturing environment. This webinar presents FLSmidth's ECS/ProcessExpert V9, featuring groundbreaking self-adaptive control technology that intelligently responds to changing process conditions without requiring multiple control models.

The solution delivers documented performance improvements of 2-3% over previous versions (7-8% total versus manual operation) while significantly reducing quality variations and enabling increased alternative fuel usage. Implementation is supported through flexible subscription models that ensure access to ongoing technological advancements while minimizing capital expenditure and providing comprehensive support services.

Transform Your Cement Operations with Expert Implementation Guidance

Take the next step in cement manufacturing excellence. See how ProcessExpert V9's intelligent, adaptive control systems can be seamlessly integrated into your existing operations, delivering immediate efficiency gains and long-term cost reductions. Our experts share real-world implementation strategies, timeline expectations, and ROI calculations to help you build a compelling business case.

Related Offerings

Products (4)

Expert Insights: ProcessExpert V9 Implementation Q&A

Frequently Asked Questions: ECS/ProcessExpert V9 Evolution