10th Dec 2024

webinar

Webinar: Grinding technology - best practices for operation and maintenance

Optimizing Cement Grinding Operations: Best Practices for Performance and Maintenance

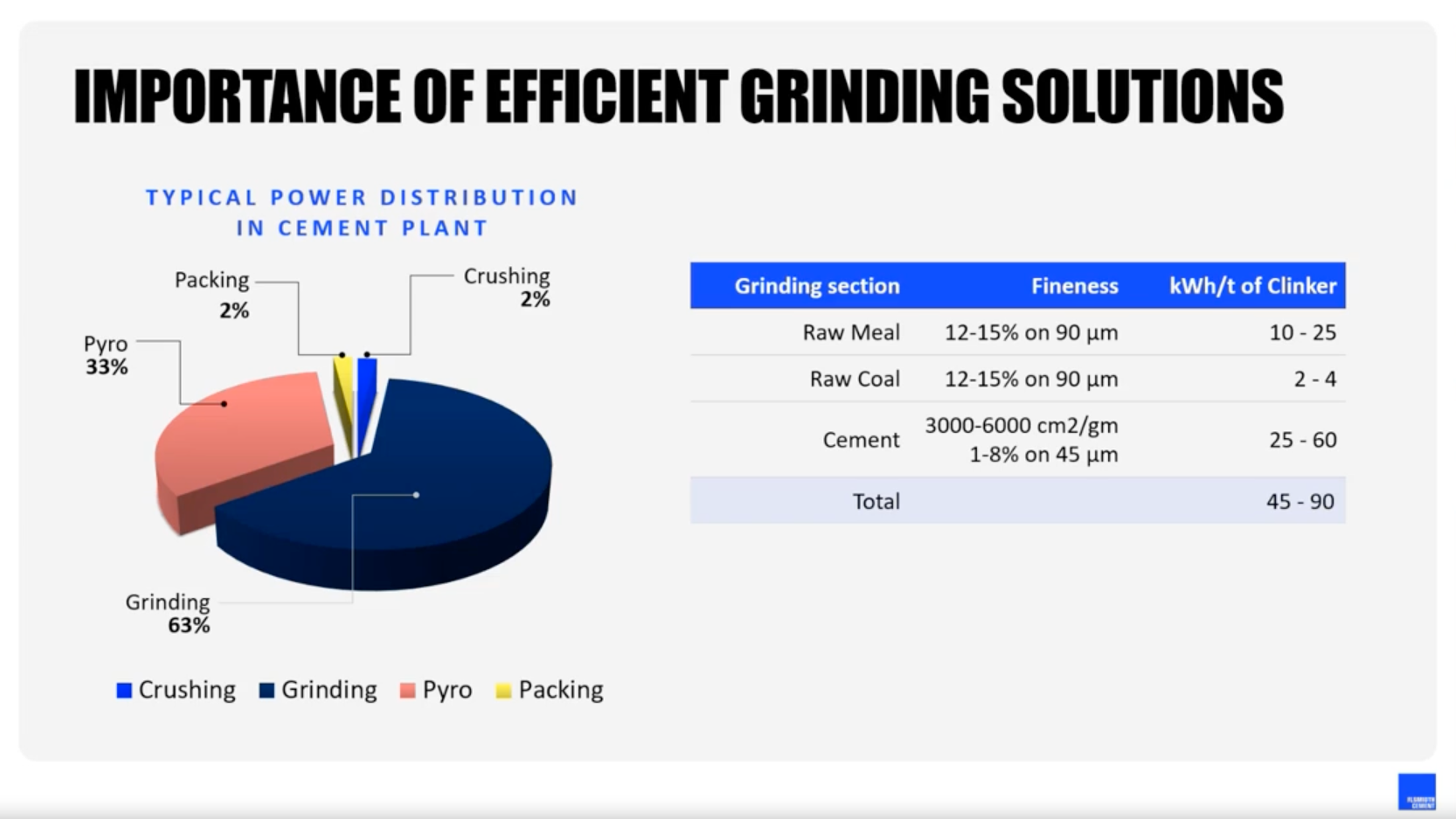

In cement production, grinding operations consume approximately two-thirds of a plant's total power. With rising energy costs and increasing pressure for operational efficiency, cement producers need effective strategies to optimize grinding performance while minimizing maintenance requirements and downtime.

FLSmidth Cement's grinding technologies and services are designed to maximize productivity, reduce energy consumption, and extend equipment life through strategic operation and maintenance practices.

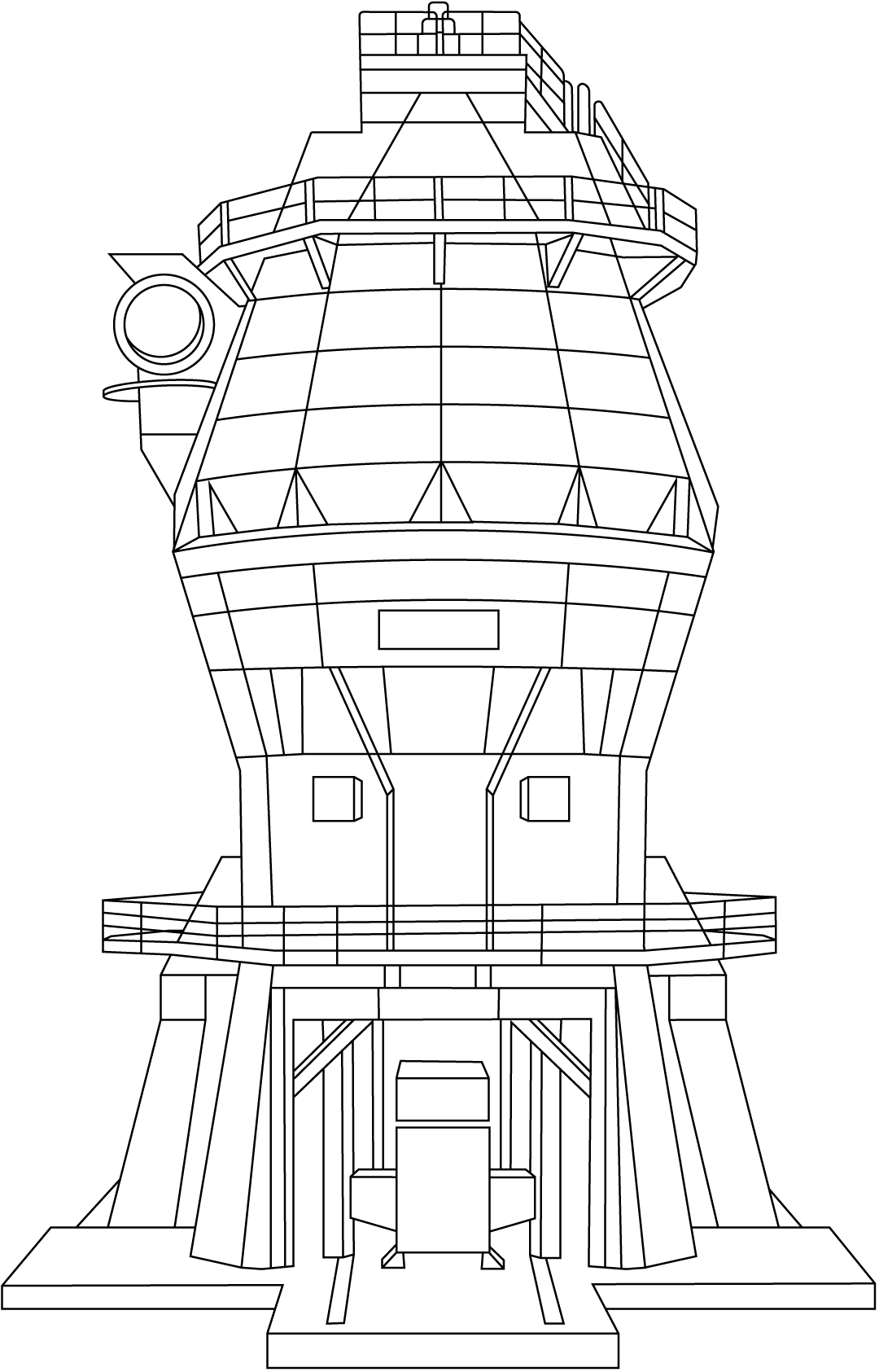

This webinar explores FLSmidth Cement's vertical roller mill technologies with particular focus on the OK™ mill, examining how operational flexibility, energy efficiency, and advanced separator designs contribute to overall plant performance. Expert-led case studies demonstrate practical applications of proactive maintenance strategies and optimization techniques that deliver measurable improvements.

Access the complete webinar recording to discover proven strategies for improving grinding efficiency, reducing wear, and maximizing equipment availability in your cement operation.

Featured Experts:

- Ahmed Seaf - Process Specialist with 16+ years of cement industry experience, including 8 years as a commissioning engineer focusing on grinding equipment

- Nick Litzenberger - Mechanical Engineer supporting mills and separators across the Americas

Key Insights Discovered:

- The flexible operation of OK™ mills with reduced numbers of rollers, allowing continued production during maintenance

- Energy savings of up to 40% compared to traditional ball mills through optimized grinding technology

- How Online Condition Monitoring Services (OCMS) detect potential failures before they impact performance

- Real-world case studies showing 58% reduction in wear rates through parameter optimization

Discover proven strategies for grinding excellence: access the full webinar on demand for detailed insights on maximizing performance, extending equipment life, and elevating your plant's operational efficiency and profitability.

Ahmed Seaf, Process Specialist

Grinding technology - best practices for operation and maintenance

Gain practical insights into optimizing grinding technology operations, improving energy efficiency, and implementing proactive maintenance strategies to enhance cement plant performance.

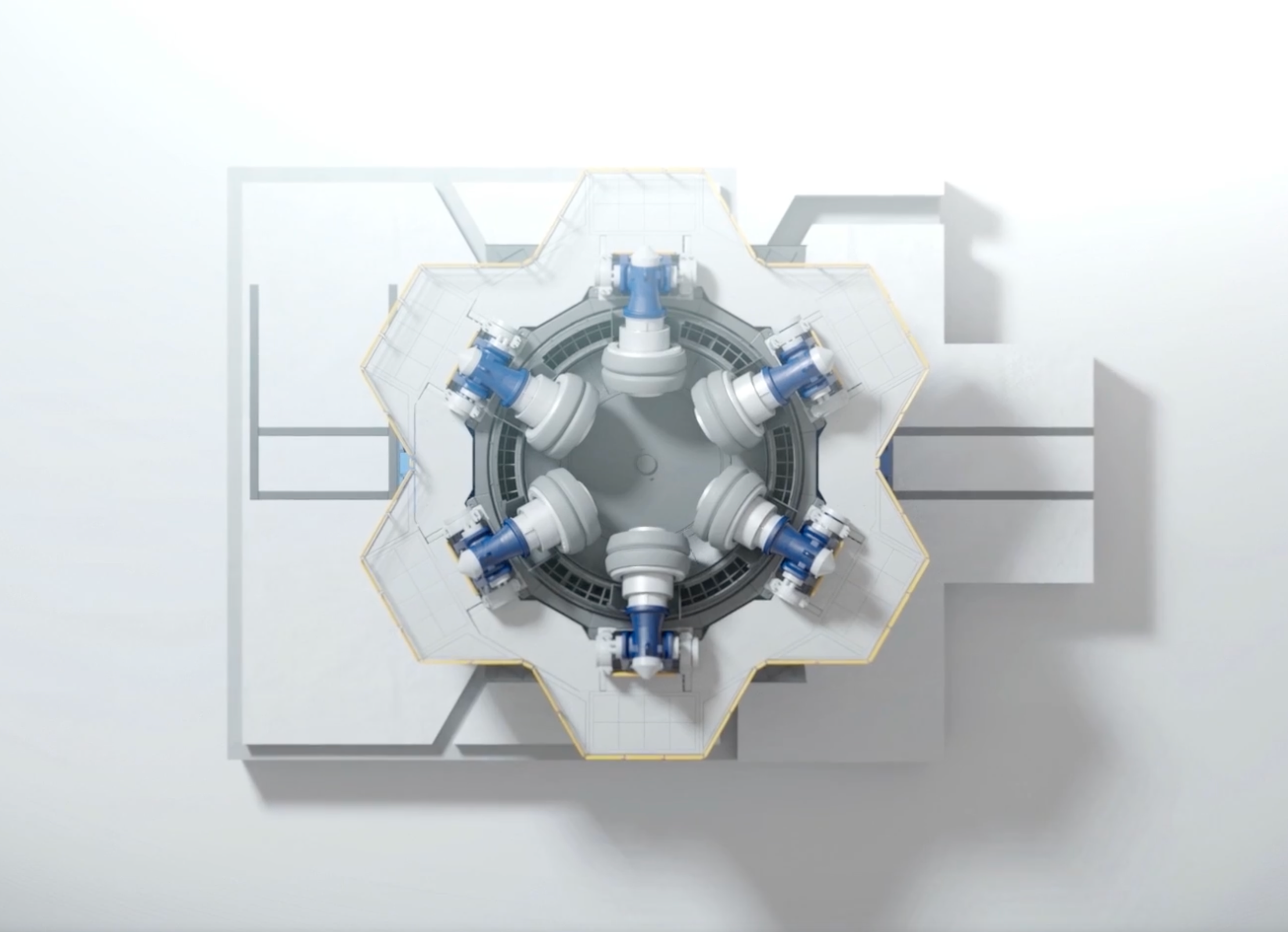

Operational Flexibility of OK™ Mills

- Capable of operating with reduced roller numbers (2 of 4 or 3 of 6) during maintenance

- Maintains 60-70% of production capacity with fewer active rollers

- Achieves desired product quality even in reduced-roller operation mode

The OK™ mill's design allows continued operation during maintenance activities, minimizing costly production downtime while maintaining required product specifications.

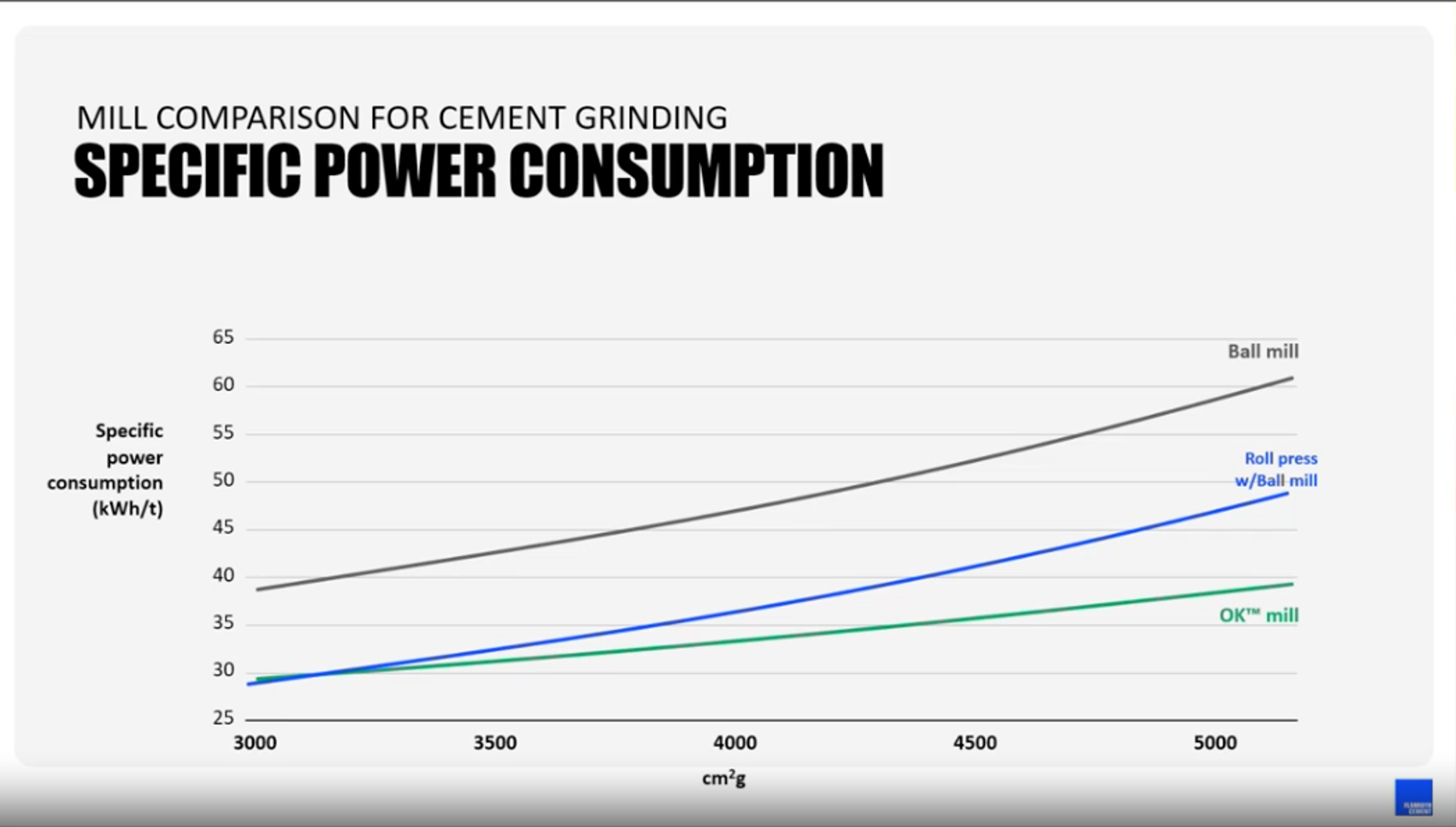

Significant Energy Efficiency Advantages

- 40% lower energy consumption compared to standalone ball mills

- 29% reduced power consumption versus roller press/ball mill combinations

- Additional 1-1.5 kWh/ton savings through advanced separator upgrades

Modern vertical roller mill technology delivers substantial operational cost reductions while maintaining or improving cement quality specifications across diverse product types.

Proactive Maintenance Through Online Monitoring

- Early detection of hydraulic system issues prevents costly failures

- Continuous monitoring of separator performance avoids bearing replacement expenses

- Real-time analysis identifies optimization opportunities for increased output

Online Conditioning Monitoring Services (OCMS) provide cement producers with actionable insights to address potential problems before they impact production, avoiding unplanned downtime and costly repairs.

Proven Results From Case Studies

- 58% reduction in wear rates through parameter optimization

- Improved separator efficiency through proper maintenance of seals and components

- Production increases of up to 50 tons/hour through bed thickness adjustments

FLSmidth's expertise in analyzing and addressing grinding issues has delivered documented performance improvements across global installations, extending equipment life while enhancing production rates.

See How Grinding Technology Optimization Transforms Cement Production

Discover proven strategies for maximizing mill efficiency, reducing maintenance costs, and extending equipment life through expert implementation of best practices and monitoring solutions. Watch the complete webinar for exclusive insights from FLSmidth Cement's grinding technology specialists.

Maximizing Grinding Performance Through Optimization

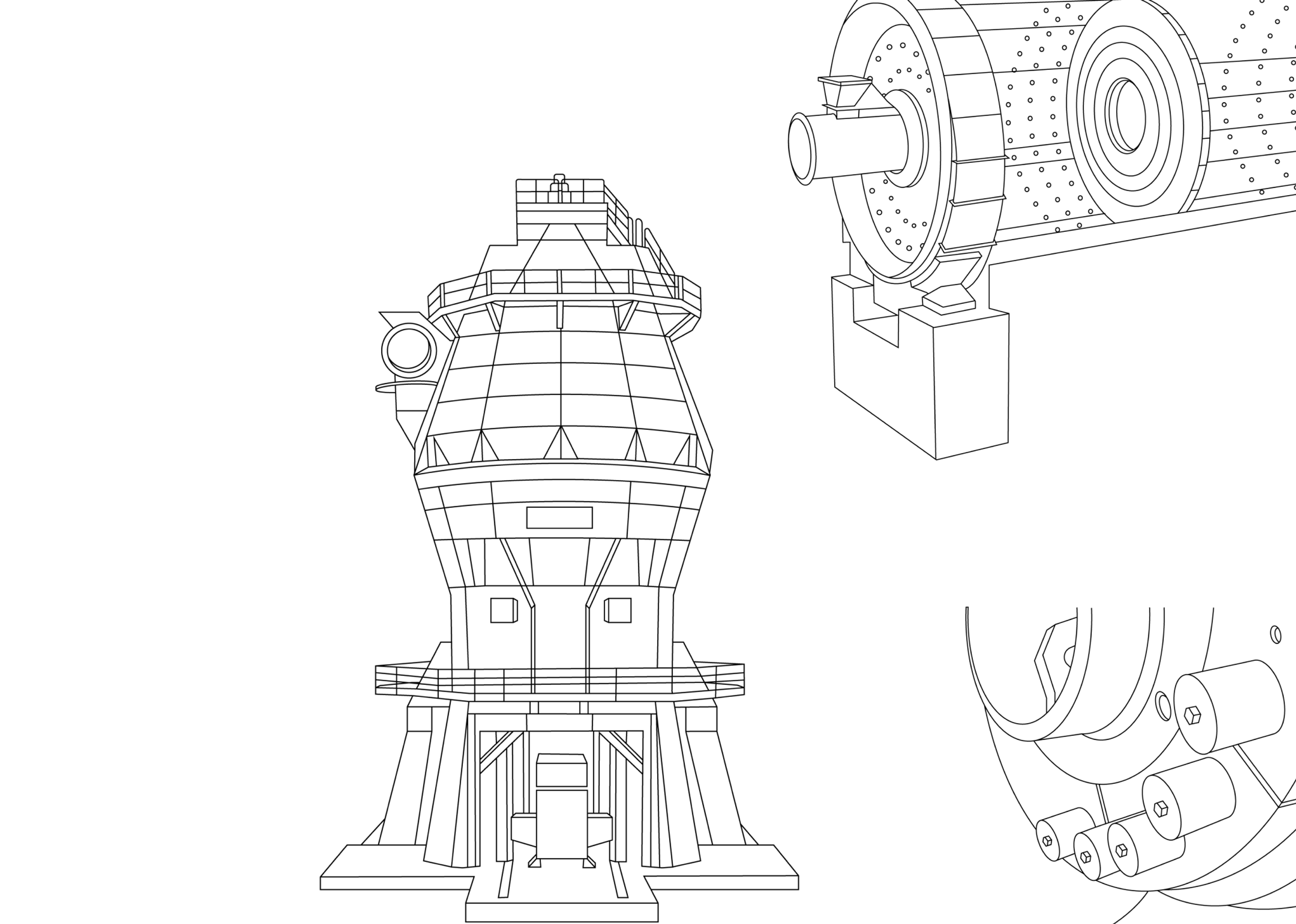

This comprehensive webinar addresses the critical challenge facing cement producers: how to improve grinding efficiency while reducing maintenance costs and extending equipment life. Ahmed Seaf presents FLSmidth Cement's vertical roller mill technologies, with particular focus on the OK™ mill's flexibility to operate with reduced roller numbers while maintaining production. The presentation demonstrates how modern grinding technology delivers up to 40% energy savings compared to traditional ball mills, with further efficiency gains possible through advanced separator designs.

A significant portion of the webinar examines how proactive maintenance strategies, including grinding system audits and online condition monitoring services, can detect potential issues before they impact operation. Real-world case studies demonstrate how parameter adjustments delivered a 58% reduction in wear rates at one plant, while optimization of bed thickness increased production by 50 tons/hour at another. The session concludes with expert answers to practical questions about mill and separator maintenance, grinding aid application, and preventing lump formation in cement silos.

Transform Your Cement Grinding Operations

Take the next step toward operational excellence with grinding technology solutions that deliver measurable improvements in efficiency, maintenance costs, and product quality. FLSmidth Cement's specialists can help you implement proven strategies tailored to your specific plant requirements.

Related Offerings

Products (4)

Services (2)

Expert Insights Q&A

Frequently Asked Questions: Grinding technology - best practices for operation and maintenance

_Raw_and_Cement_Mill.png?w=3840&q=80&auto=format)